° To provide various high end printing in packaging.

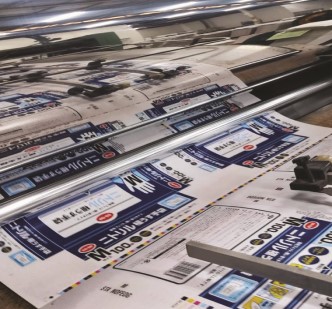

° Service in offset including the top & high range of colors printer with quality print & enhance special effects

To provide high quality design & proficient to handle own design, artwork to suit customer’s requirement for packaging products.

° Latest CTP technology with fast turn around to plate production.

° High accuracy in print to print registration & high productivity.

To provide flexibility to sheet roll form with variety printing sizes at accuracy with high productivity.

° To provide auto die cut & auto stripping with accurate & consistent die cut pressure for perforating window & creasing lines.

° Accepting customized shape & design job.

° Support gluing of big/medium/small box.

° Support bottom lock design, side glue, 2-4 point glue.

ex: Catheters box, Display box, Gift box, Condom box.

To provide special surface treatment- cured by UV light to make the surface coating glossy & to resist smudging & maintain a professional high quality standard appearance.

To provide surface glossiness. To strengthen & beautify product image. Adds a layer of protective coating with laminating films to make the surface glossy or matte effect. Such lamination improves the sturdiness & water resistance.

To enhance the packaging surface to be most shinny, glossy & smooth with apply high heat & pressure to make the product more impressive, presentable & high standard.

Value-added process by using silver or gold foil to beautify the product

° To laminate the inner liner and medium into a single facer.

° To laminate the single facer with the duplex board.

° To strengthen the boxes & to serve as a cushioning/protection of customer’s products.

° Flexo printing on shipper carton. Quick drying flexo inks on all types of RSC & FOL carton.

° Accept materials Single wall/Double wall & White & Brown Kraft paper materials.

Snack Box

Snack Box

Snack Box

Snack Box

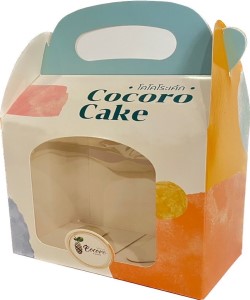

Cake Box

Cake Box

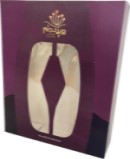

Gift Box

Tray Box

Window Patching Box

Lid & Base

Face Mask

Condom box

Inner box with Window Patching

Display Box

Inner Box with Window Patching

Cake Box

Glove Sample Pack

Glove Box

Paper Bags

Paper Bags

Paper Bags

Paper Bags

Single Face Lamination

Corrugated Pizza Box

Carton

Nesting

188 Moo 1 Kanchanavanich RD.,

Tambol Samnukkam,

Sadao Songkhla, 90320 Thailand.

Tel: 006674-412780

Fax: 006674-412793